Induction Motor Fault Diagnosis Using Vibration and Motor Current

Nakhaeinejad, Mohsen & Ganeriwala, SuriSpectraQuest Inc., 8227 Hermitage Road, Richmond, VA 23228

Tel: (804)261-3300 www.spectraquest.com

Published: June, 01 2010

Abstract

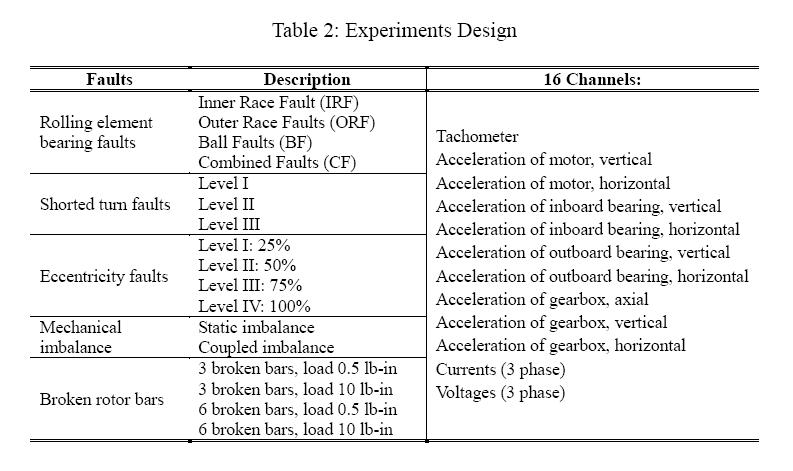

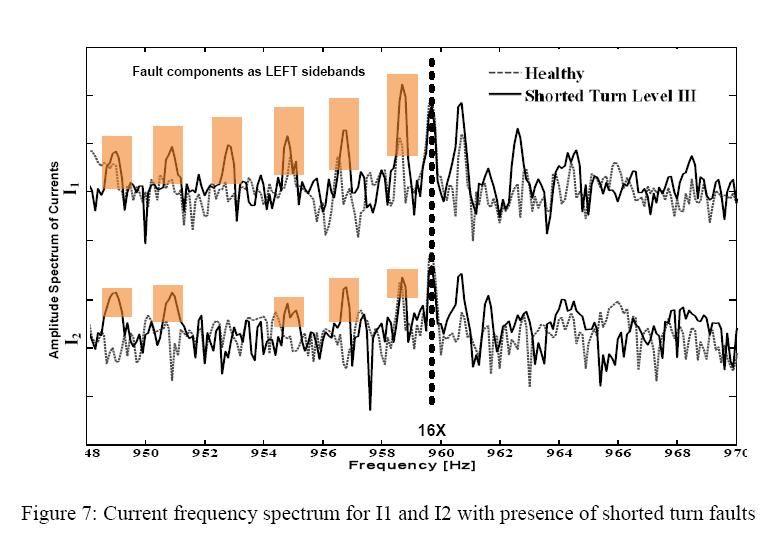

This experimental study investigates the effect of mechanical and motor electrical faults in rotating machinery. Machinery Fault Simulator (MFS-Magnum) with a 3-phase, 0.5 HP induction motor was used for experiments. Mechanical and electrical faults such as shorted turn, broken rotor bars, mechanical imbalance, rolling element bearing faults, and rotor eccentricity were introduced. For each case, 16 channels of signal including shaft speed, vibration, motor voltages and currents were monitored and studied in time- and frequency-domains. The data for both vibration and motor current/voltage on all three phases were analyzed. Results indicate significant components in motor current spectrum due to shorted turn and rotor eccentricity faults. However, the effect of mechanical imbalance, shaft bearing faults and static eccentricity on current spectrum is not significant.

Keywords: Diagnosis; MCSA; power quality; rotating machinery; vibration analysis; motor current analysis

Introduction

Diagnostics and condition monitoring in industrial rotating machinery can avoid machine downtime, and save time and money. Faults in rotating equipments can generate vibration of mechanical parts or change the power quality of the motor. Also, electrical faults in induction motor can change the behavior of the motor reflecting in motor currents. Motor current signature analysis (MCSA) techniques process motor currents to diagnose the machine. Therefore, a comprehensive study of motor current/voltage and vibration response under faults is needed for such diagnostics. Induction motors are critical components of many industries and are considered to be the ‘power horses‘ of the industry. This paper focuses on the application of Motor Current Signature Analysis (MCSA) to diagnose faults in three-phase induction motors. MCSA has the advantages of non-invasive and online monitoring techniques [1]. A review of publications in the field of MCSA reveals inverse relationship between fault detection ease and importance to the user of that fault detection [2]. Also the amount of literature available on the application of MCSA on broken rotor bars is considerably high compared to the other faults.