Hands-on Training Systems for Shaft/Coupling Alignment

Hands-on Training Systems for Shaft/Coupling Alignment

Misalignment is the second most commoncause of machinery malfunction. A poorlyaligned machine can cost a factory 20% to 30%in machine down time, replacement parts, inventory,and energy consumption. The payback fromaligning machinery to extend the operating lifeand optimize process conditions is very large.At first glance it seems that aligning two matingshafts should be a simple process. In the realworld, however, there are many complicating factors.For example, either one or both shafts maybe locked or have limited rotation. One or bothshafts may float axially. The machine may havea soft or sprung foot at one or more locationsalong with a soft and/or warped baseplate. Thealignment positions may become bolt bound.Keeping in mind that acceptable final alignmentis typically less than 2 mils, maintenance professionalsoften find it very challenging to attainproper alignments.Anacceptable alignment requires a well-trainedalignment personnel. SQi offers a complete package for training shaft alignment. The training package includes:

- Hands-on device to perform controlled experiments

- Alignmentsoftware

- Comprehensive shaft alignmenthandbooks

- Shaft alignment workbook

- Shaft alignment study guide

Spectra Quest’s alignment training solution is a comprehensive tool to train, learn, and practice shaft alignment.

The Ultimate Tool for Teaching Shaft Alignment

SQi’s Shaft Alignment Trainer (SAT) is the most comprehensive device on the market for shaft alignment training. It is designed for studying a wide variety of problems that can arise when two shafts are misaligned. It is a hands-on trainer for maintenance professionals. It provides a unique mechanism for studying soft and sprung foot. It is a realistic simulator with a one inch diameter shaft that fits standard couplings. Its modular design facilitates simulation of multiple element drive trains. The SAT is available in a two train and in a three train configuration. Each SAT incorporates two fully adjustable modular units featuring horizontal jack bolts, calibrated and reference dials, and replaceable feet. The three train SAT adds a fixed module which simulates a non-adjustable machine, but, the shaft can be offset and axially floated.

The SAT system is robust, portable, and simple to use. The device has ample space to mount dial indicators and laser heads for alignment training. The innovative design makes it easy to extend the base to accommodate additional main modules for simulating multiple machine element trains. This can be done in both linear and perpendicular configurations. The SAT provides a range of benefits in developing an understanding of alignment problems.

SAT Benefits

- Practice and learn different shaft alignment methods using dial indicators or lasers.

- Practice alignment procedure when one or both shafts are locked

- Practice alignment when one or both shafts have limited rotation.

- Practice alignment when the machine is bolt bound.

- Recognize and correct soft foot conditions in one to three feet.

- Recognize and correct sprung foot conditions, from one to four feet.

- Study effect of coupling types on alignment procedures.

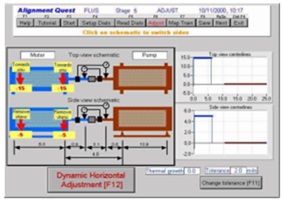

AlignmentQuest Software

The AlignmentQuestsoftware enables the user to employ conventional, readily available dial indicators to their maximum potential. This is accomplished by using a built-in inclinometer to input accurate rotational data. The software then calculates the proper movements needed to bring the shafts into near perfect alignment. For bolt bound or similar conditions, it is only necessary to click the mouse on the other machine to see the opposite set of alignment data and graphical orientation.

With the limited swing feature, it is no longer necessary to use a mirror to read the indicators, thereby minimizing the potential for error and the software will alert the user to the expected reduction in accuracy. The program is able to map the 360 degree rotation and check each degree of rotation for human and/or hardware errors that might be contributing to a false reading. Shaft alignments can be made on vertical machines and multi-machine trains and provisions for thermal growth are possible. Machine definition, measurement data, and alignment steps with time/date for all equipment in the plant can be archived and retrieved as needed. Custom reports can easily be generated and data can be exported for further analysis.

SAT Features:

- Misalignment in both horizontal and vertical planes, both angular and parallel (four horizontally mounted jack bolts with calibrated dials and slotted shims for elevation).

- Calibrated parallel and angular misalignment easily introduced.

- Learn to recognize and correct soft and sprung foot conditions.

- Modular design for easy customization.

- Portable, robust, and comprehensive alignment trainer.

AlignmentQuestFeatures:

- Vivid, easy to view color graphics.

- Align multiple machine trains, horizontally or vertically mounted.

- Built-in step by step tutorial with intuitive, easy to remember procedures.

- Perform shaft alignment under limited swing conditions using any amount of angle. The software alerts the user to the precision obtainable under such conditions.

- Self diagnostics to detect human and hardware errors.

- Fixed and adjustable machines can be interchanged.

- Optimum alignment solutions automatically suggested and “what-if” scenarios performed.

- Sag compensation indicator.

- Adjustable tolerance limit.

- Creates a 360 degree rotational map of the shaft rotation, useful in visualizing the full operation of the machine.

- Create a machinery database for the entire facility.

- Archive alignment data, including steps, with date/time.

- Export data for further analysis.

- Generate comprehensive custom reports.

Complete Training Materials

Shaft Alignment Handbook is the most comprehensive book ever written on the subject of aligning rotating machinery. This single source reference offers a comprehensive analysis of coupled rotating machinery systems, providing practical guidelines for solving complex alignment tasks fast and accurately. Shaft Alignment Handbook covers all practical information related to Shaft Alignment.

Shaft Alignment Workbook provides valuable information on the basic knowledge needed to begin understanding shaft alignment of rotating machinery. Reviews the importance of alignment, preliminary steps you should perform, how to measure shaft positions, and basic alignment modeling techniques to correct a misalignment condition. Widely accepted misalignment tolerance guide included. Outstanding field reference guide and recommended manual for shaft alignment certification exams.

Shaft Alignment Self Study Guide is a companion book to the Shaft Alignment Workbook that leads you through the eight chapters of the Workbook, supplements the information for additional understanding of the topics, and then quizzes you at the end of each of the eight lessons. Shaft Alignment Self Study Guide system is the most effective way to teach yourself how to align industrial rotating machinery and invaluable in preparing you for the shaft alignment certification exams. It is a great self paced training tool for anyone preparing for certification exams on shaft alignment of industrial rotating machinery.