Machinery Fault & Rotor Dynamics Simulator

|

View Presentation Print Brochure |

|

|

Why MFS-RDS

Features

Specifications

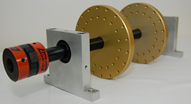

Basic MFS-RDS

Option Kits

Packages

An innovative tool to study oil lubricated journal bearings

SpectraQuest’s Machinery Fault & Rotor Dynamics Simulator (MFS-RDS) is an innovative tool to study the dynamic behavior of rotors supported by oil lubricated journal bearings, as well as other common machinery faults, such as balancing and resonance study. An oil pump is provided with the simulator to drive the lubrication fluid. In addition, it provides different bearing clearance selection and controllable lubrication oil pressure for rotor dynamics whirl and whip phenomena.Numerous Experiment Possibilities

|

|

|

Features

- Rotor shaft specially designed for fluid film bearing rotor dynamics simulation

- Different bearing clearance selection and controllable lubrication oil pressure for rotor dynamics study

- Convenient installation of proximity probes

- Rigid, slippage-free operation

- Split bracket bearing housing for easy rotor assembly interchanges

- Specialized bearings and rotors with split collar ends for easy replacement and installation

- Rotor shaft slides without removing mounted components for easy changes

- Couplings, rotors, bearings, and shaft can be changed without removing bearing housings

- Convenient alignment with jackscrew

| Electrical | |

| Motor | 3 Phase, 1/2 HP motor, pre-wired self-aligning mounting system for easy installation/removal |

| Drive | 1/2 HP variable frequency AC drive with multi-featured front panel programmable controller |

| RPM range | 0 to 6000 rpm (short duration) variable speed |

| Tachometer | Built-in tachometer with LCD display and one pulse per revolution analog TTL output for DAQ purposes |

| Voltage | 115/230 VAC, Single phase, 60/50 Hz |

| Mechanical | |

| Shaft Diameter | 1/2″ diameter; Turned, Ground, & Polished (TGP) steel |

| Rotor Base | 30″ long, completely movable using jack bolts for easy horizontal misalignment and standard shims for vertical misalignment. Pinned for easy realignment. |

| Bearing | Two full fluid film bearings with multiple oil inlet prots, provisions to mount proximity probes at any angle. Bearing mounts can be mounted in nine different position for variable rotor span |

| Oil Distribution System | Pump, pressure gage, stainless steel oil tank, back flow safety switch, pressure interlock gauge. |

| Rotors | Two 6″ aluminum with 36 threaded holes at 10 degree intervals for introducing unbalance |

| Safety Cover | Lockable clear, impact resistant hinged plastic cover with motor interlock switch to shut down motor when cover is raised |

| Foundation | 1/2″ die cast aluminum base, base stiffener and eight rubber isolators |

| Physical | |

| Weight | Approximately 140 lb |

| Dimensions | L=50″ (125cm), W=14″ (36cm) , H=23″ (58cm) |

Basic Machinery Fault & Rotor Dynamics Simulator System includes:

- 1/2 HP variable frequency AC drive with multi-featured front panel programmable controller

- 3 Phase, 1/2 HP motor, pre-wired self-aligning mounting system for easy installation/removal

- Built-in tachometer with LCD display and one pulse per revolution analog TTL output for DAQ purposes

- Pressurized fluid film bearings with features to change bearing clearance, length, and type.

- Includes two full sleeve bearings with multiple oil inlet prots, tapped holes for mounting two proximity probes at 90 degrees, ability to rotate probe at any angle.

- Oil distribution and pressure adjustment system including of pump, pressure gage, stainless steel oil tank, back flow safety switch, pressure interlock gauge.

- Bearing inserts with 0.002″ clearance

- Extended 30″ rotor base to allow for rotor dynamics experiments up to three critical speeds and whirl/whip phenomena investigation, and five bearing mounting positions for shaft span reconfiguration

- Vibration isolators mounts and base stiffener

- Three steel disks with one row of holes

- Alignment system with calibrated reference dials and jack bolts

- One 1/2″ TGP straight steel shaft

- Impact resistant clear safety cover with safety interlock

- Balance weight kit

- Allen wrench set

- 24V Power supply

- Cover support

- Comprehensive operations manual

| The MFS-RDS provides you with a basic setup for performing rotor dynamics experiments and learning vibration signatures of different machine malfunctions. However, a detailed investigation of a particular phenomenon will require additional attachments and fixtures. SpectraQuest has designed option kits for performing different in-depth studies on the MFS-RDS. | |

Training Curriculum Manual (SQI-TRCM) | |

|  |

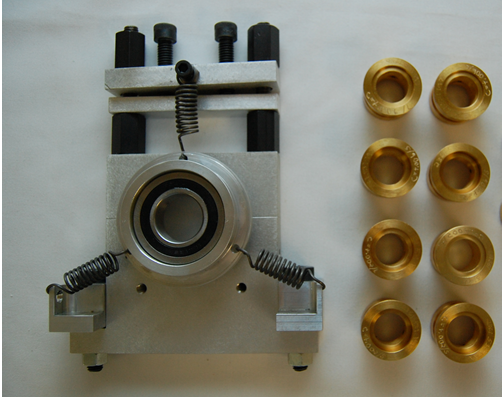

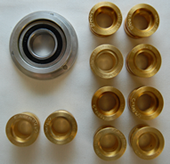

Oil whirl/whip in-depth study kit for 1/2″ shaft (MR-OWSK-1/2) | |

|  |

Oil whirl/whip in-depth study kit for 3/4″ shaft (Requires MR-SCK-3/4 and MR-OWSK-1/2) (MR-OWSK-3/4) | |

|  |

3/4″ Shaft Conversion Kit (MR-SCK-3/4) | |

|  |

3/4″ shaft bearing loader (Requires MR-SCK -3/4) (M-BL-3/4) | |

|  |

3/4″ Bearing Fault Kit (Requires MR-SCK -3/4) (M-BFK-3/4) | |

|  |

Eccentric Rotor (Requires MR-SCK-3/4) (M-ER-3/4) | |

|  |

Cocked Rotor (Requires MR-SCK-3/4) (M-CR-3/4) | |

|  |

Coupling Type Set (Requires MR-SCK-3/4) (M-CK-3/4) | |

|  |

Centrally Bent Rotor Shaft for Balance Studies (MR-BRS-3/4) | |

| |

Coupling-End Bent Rotor Shaft for Balance Studies (MR-CBRS-5/8) | |

| |

Sleeve Bearing Resonance Study Kit (M-SBK-1/2) | |

|  |

Rolling Bearing Resonance Study Kit (M-RBK-1/2) | |

|  |

Higher Resonance Study Kit (M-RDK-1/2) | |

|  |

3/4″ Shaft Sleeve Bearing (grease lubricated) kit (M-SBK-3/4) | |

|  |

Cocked Bearing Housing (M-CBM-3/4) | |

|  |

1″ Shaft Bearing Study Kit (MR-BSK-1) | |

|  |

1″ shaft Bearing Loader (Requires MR-BSK-1) (M-BL-1) | |

|  |

1″ shaft bearing fault kit (Requires MR-BSK-1) (M-BFK-1) | |

|  |

Crack Shaft Study Kit (Requires MR-SCK -3/4) (MR-CSRK-3/4) | |

|  |

Fan Vibration Kit (M-FVK-3/4) | |

|  |

Mechanical Rub Kit (M-MRK) | |

|  |

Damped Bearing Housing Kit (Requires MR-SCK -3/4) (M-DBHK-1/2) | |

|  |

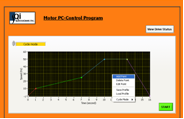

PC Motor Control Kit (M-PCK) | |

|  |

Shaft Alignment Kit (M-ATK) | |

|  |

High Value Combination Packages

The MFS-RDS provides a basic setup for performing rotor whirl/whip experiments and learning vibration signatures of different machine malfunctions. However, a detailed investigation of particular and more advance vibration phenomena will require additional attachments and fixtures which are available through optional kits. Depending on the package selected, you get a 6% to 8% discount over separately purchased items.| Package # 1 : | Basic MFS-RDS+ Kits for in-depth studies of rotor whirl/whip phenomena with 1/2″ and 3/4″ diameter shafts |

| Package # 2 : | Basic MFS-RDS+ Kits for in-depth studies of oil whirl/whip, alignment, balancing and resonance up to third critical frequency issues |

| Package # 3 : | Basic MFS-RDS+ Kits for in-depth studies of oil whirl/whip, alignment, balancing, resonance, and bearing defect issues |

| Package # 4 : | Basic MFS-RDS+ Kits for in-depth studies of oil whirl/whip, alignment, balancing, resonance, bearing defect, shaft crack, fan vibrations, mechanical rub and damping issues |

| Package # 5F : | Basic MFS-RDS+ Kits for in-depth studies of oil whirl/whip, alignment, balancing, resonance, bearing defect, shaft crack, fan vibrations, mechanical rub, damping issues; plus PC operation, shaft alignment kit and force measurement of both bearings |

| Option kit | PKG 1 | PKG 2 | PKG 3 | PKG 4 | PKG 5F | |

|---|---|---|---|---|---|---|

| Training Curriculum Manual | SQI-TRCM | x | x | x | x | x |

| Oil whirl/whip in-depth study kit for 1/2″ shaft | MR-OWSK-1/2 | x | x | x | x | x |

| 3/4″ Shaft Conversion Kit | MR-SCK-3/4 | x | x | x | x | x |

| Oil whirl/whip in-depth study kit for 3/4″ shaft (Requires MR-SCK-3/4 and MR-OWSK-1/2) | MR-OWSK-3/4 | x | x | x | x | x |

| Eccentric Rotor (Requires MR-SCK-3/4) | M-ER-3/4 | x | x | x | x | |

| Cocked Rotor (Requires MR-SCK-3/4) | M-CR-3/4 | x | x | x | x | |

| Coupling Type Set (Requires MR-SCK-3/4) | M-CK-3/4 | x | x | x | x | |

| Centrally Bent Rotor Shaft for Balance Studies (Requires MR-SCK-3/4) | M-BRS-3/4 | x | x | x | x | |

| Coupling-end bent rotor shaft for alignment studies (Requires MR-SCK -3/4) | M-CBRS-3/4 | x | x | x | x | |

| Rolling bearing resonance study kit | MR-RSK-1/2 | x | x | x | x | |

| Higher Resonance Study Kit | M-RDK-1/2 | x | x | x | x | |

| Sleeve Bearing Resonance Study Kit | M-SBK-1/2 | x | x | x | ||

| Cocked Bearing Housing | M-CBM-3/4 | x | x | x | ||

| 3/4″ Shaft Sleeve Bearing (grease lubricated) kit | M-SBK-3/4 | x | x | x | ||

| 3/4″ Bearing Fault Kit (Requires MR-SCK -3/4) | M-BFK-3/4 | x | x | x | ||

| 3/4″ shaft bearing loader (Requires MR-SCK -3/4) | M-BL-3/4 | x | x | x | ||

| 1″ Shaft Bearing Study Kit | MR-BSK-1 | x | x | x | ||

| 1″ shaft bearing fault kit (Requires MR-BSK-1) | M-BFK-1 | x | x | x | ||

| 1″ shaft Bearing Loader (Requires MR-BSK-1) | M-BL-1 | x | x | x | ||

| Mechanical Rub Kit | M-MRK | x | x | |||

| Damped Bearing Housing Kit (Requires MR-SCK -3/4) | M-DBHK-1/2 | x | x | |||

| Crack Shaft Study Kit (Requires MR-SCK -3/4) | MR-CSRK-3/4 | x | x | |||

| PC Motor Control Kit | M-PCK | x | ||||

| Fan Vibration Kit | M-FVK-3/4 | x | x | |||

| Shaft Alignment Kit | M-ATK | x | ||||

| Vertical and Horizontal Bearing Force Transducer for 1/2″ to 1″ Shafts | M-FTVH | x |

News Releases

- SpectraQuest Introduces Maintenance 4.0 Solution for Manufacturing Workforce Skills Enhancement

- Watch video of pump cavitation test on YouTube

- Watch video of Wind Turbine Simulator on YouTube

- Watch demo of structural testing on SpectraQuest's wind turbine blades using NI's SC Express at NIWeek Keynote Session

- Watch demo of structural testing on SpectraQuest's wind turbine blades using NI's SC Express data acquistion on Engineering TV

- SpectraQuest introduces the Kinematics and Dynamics of Machines (KDT) Series

- SpectraQuest introduces the Vibration Fundamentals Trainer(VFT)

About Us

Spectra Quest, Inc. is dedicated to providing state-of-the-art systems for enhancing product reliability and quality assurance. We develop and manufacture training and diagnostic systems for industrial maintenance and vibration analysis. Our flagship Machinery Fault Simulator (MFS) has been sold in over 50 countries [ Read More About Us]