VibroMet 500V: Single Point Laser Doppler Vibrometer

Published:

Abstract

This paper discusses a Single Beam LDV product offered by MetroLaser; specifically it discusses the VibroMetTM 500V single point laser Doppler vibrometer (LDV). A discussion of the single point LDV system is presented including its principles, hardware, software, capabilities and specifications, applications and examples. To avoid confusion the single point system is referred to as the 500V but references to the 500 and an earlier VibroMetTM 100 are made throughout since they have been around longer and some of the data presented here were collected with these earlier versions. All of the single point VibroMetTM share numerous similarities; a major difference is the visible pointer laser included in the new VibroMetTM 500V

Introduction

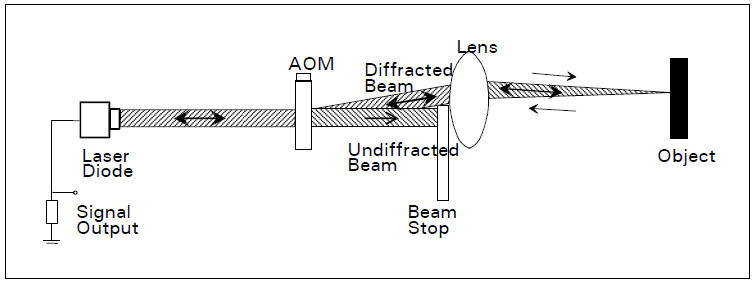

The VibroMetTM 500V (and its predecessors the VibroMetTM 500 and the VibroMetTM 100) is a heterodyne laser Doppler vibrometer that employs self-mixing1,2 to mix the object beam with the reference beam (also known as local oscillator) on the face of the photodetector. The system employs a diode laser at a wavelength of 780 nm to produce both the object beam (to illuminate target) and the reference beam (local oscillator) and a Bragg cell acousto-optic modulator (AOM) to impress a carrier frequency. The photodetector is an integral part of the diode laser module commonly used to monitor laser power. The LDV system is based on a patented electro-optical configuration3 and is schematically illustrated in Figure 1. Most of the light from the laser diode comes out of the laser and is collimated by a custom lens. The collimated beam goes through the AOM where part of the beam is diffracted and frequency shifted (typically 35 to 40 MHz); this is the object beam. Part of the collimated beam (the zero order) goes through the Bragg cell undiffracted and it is blocked by a beam stop. The object beam illuminates the target and part of the light scattered by the target goes back into the AOM where it is diffracted and frequency shifted again (for a total now of 70 to 80 MHz). This effect is known as double frequency shift and has the beneficial effect of creating a carrier frequency at double the RF drive thus helping to separate the signal from any possible RF noise. The frequency shifted object beam enters the diode laser where it experiences gain and it is mixed with the reference beam (a small portion of the diode laser beam normally employed to monitor laser power). An optional focusing lens is shown on Figure 1. it is employed to create a small focused beam that may be needed for some applications. The standard VibroMetTM 500V does not include a focusing lens but instead uses a collimated object beam. The collimated beam allows the VibroMetTM 500V to work at variable distances from a few cm to several meters without the need to adjust or align any optical components.

Fig 1: Schematic Diagram of MetroLaser VibroMetTM