Air Bubble and Cavitation Vibration Signatures of a Centrifugal Pump

Lin Liu, Zhuang Li & Suri GaneriwalaSpectraQuest Inc., 8227 Hermitage Road, Richmond, VA 23228

Published: May, 01 2006

Abstract

In this work, a centrifugal pump was tested for its vibration signatures under different operational conditions. The two abnormal operating conditions studied are air bubble and cavitation. A transparent plastic cover was used in the experiments to observe the cavitation. It was found that the pump has higher vibration amplitude in the axial direction than in the radial direction. From the experiments, it was also determined that significant amount of air bubbles will increase vibration component associated with impeller vane pass frequency significantly. Cavitation might excite high frequency structural resonance. It may also reduce the impeller vane pass frequency vibration. Although cavitation is less likely to happen on a slow speed pump, it will develop very fast if it happens

Introduction

A pump is a mechanical device used to move liquids. Mechanical energy is transformed into hydraulic energy at the pump. Pumps can be classified into two categories: displacement pumps and centrifugal pumps. In this work, a centrifugal pump was tested and studied.

>In a centrifugal pump, a rotating element called an impeller is enclosed in a case. The fluid to be pumped enters into the case through the suction piping into the impeller and is forced out the discharge side of the pump by means of centrifugal force pushing the fluid out radially through the impeller. The fluid is discharged at a higher pressure and a higher velocity. The major portion of the velocity energy is then converted into pressure energy by means of a volute or by a set of stationary diffusion vanes surrounding the impeller periphery. In a pump, vibration is caused by the interaction between the moving pump impeller and the stationary parts of the pump such as the volute and the diffuser vanes. Also, vibration is caused by the interaction between the impeller blades and the fluid being pumped.

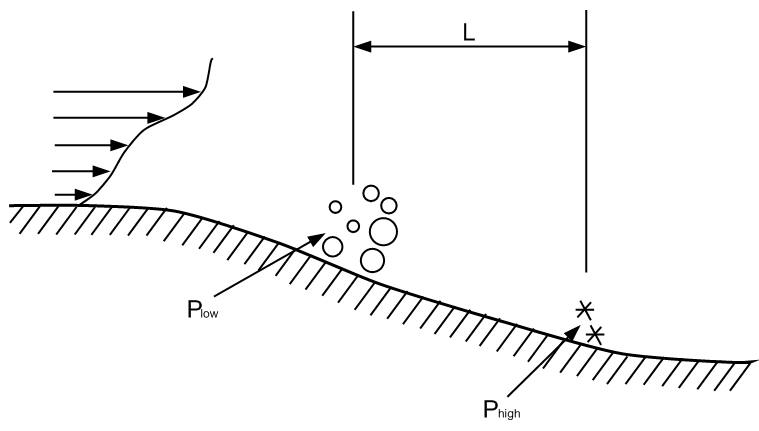

One of the important phenomenon in pump is cavitation. Cavitation occurs when the pressure of the fluid drops below the vapor pressure for the temperature of the fluid. When this pressure drop occurs, whether it is a system pressure drop or a localized pressure drop, voids or cavities (bubbles) will form in the liquid. These bubbles implode or collapse when the fluid moves through impeller to the high pressure side of the pump, causing the impeller to erode. These implosions tear out tiny pieces of the metallic surface near which they implode. This can be very damaging and eventually the impeller will fail.

Fig 1: Schematic representation of the cavitation process.

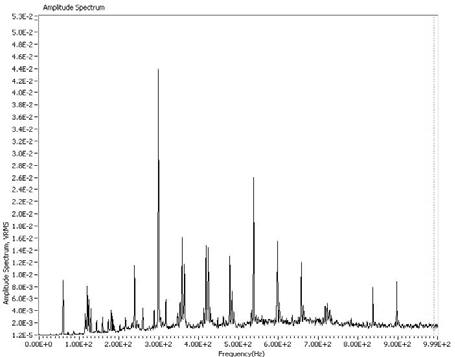

Fig 2: Pump Vibration with Appearance of Cavitation (3616 RPM)-Axial Vibration (1 KHz)