Effects of Clearance on Damping in Fluid Film Bearing

Zhuang Li & Suri GaneriwalaSpectraQuest Inc., 8227 Hermitage Road, Richmond, VA 23228

Published: June, 01 2007

Abstract

Clearance of a fluid film bearing is a critical parameter affecting the eccentric ratio as well as dynamic characteristics of the rotor system. Four shaft/rotor configurations have been tested on Spectra Quest's Rotor Dynamics Simulator. For each test configuration, three bearing sets with different clearances were used to investigate the effects of clearance on damping in the fluid film bearing. It is observed that an increase in clearance will increase the modal damping because of the higher shear deformation. The experimental results also show that the critical speed and damping in the coast-down process are lower than those when the machine starts up.

Introduction

In Wikipedia, the bearing is defined as a device to permit constrained relative motion between two parts, typically rotation or linear movement.1 Fluid bearings use a thin layer fluid to support the bearing load so that there is no metal-to-metal contact when the shaft rotates, which is the able to reduce wear. The portion of the rotating shaft at the bearing is often called the journal. The working mechanism of fluid film bearing was discovered more then 100 years ago. "Without relative motion or a converging clearance, no pressure or load capacity will be developed. It is the pressure in the lubricant film that carries the external load and separates the solid surfaces." 2 Figure 1 illustrates a typical hydrodynamic bearing where the fluid is pumped in through an orifice. When the shaft spins with an angular velocity of ω, the fluid is dragged into a convergent clearance. Due to gravity, eccentricity, manufacturing imperfection, misalignment, unbalance, and other factors, the rotor cannot always be perfectly centered. Therefore, the fluid forms a wedge (h1 is larger than h0 in Fig. 1) which generates pressure to support the applied load. By assuming velocity continuity, the fluid velocity on the surface of the journal is the same as the velocity of the journal (V) at the contact point, and is zero on the surface of the bearing. The fluid velocity distribution through the thickness is normally not linear, as shown in Fig.1. This is presumably caused by fluid loss due to end leakage. So the fluid flows not only in the radial direction following the rotating of the shaft, but also in the axial direction. As a result, the average velocity of the fluid is slightly less than V/2.

As the fluid friction is proportional to the viscosity as well as the velocity gradient, an increase in the running speed will increase the heat generation. On the other hand, lubricant's viscosity is very sensitive to temperature. In the meanwhile, the dynamic parameters, namely stiffness and damping, are strongly affected by the fluid viscosity. Consequently, when a machine is speeding up, an increase in temperature will decrease the bearing stiffness as well as damping, which will further influence the dynamic behavior of the rotor system.

Bearing clearance is also an important parameter in rotor dynamics. For a cylindrical bearing, the diametral clearance is defined as the difference between the bearing and shaft diameters. The eccentric ratio, which is inversely proportional to the clearance, has a significant effect on the dynamic characteristics of a rotor system. In addition, a change in the clearance will change the fluid film and the shear stress, which will further affect the energy dissipation caused by the shear deformation. Therefore, the clearance has quite complicated effects on the performance on a rotor system. In this study experiments have been carried out to investigate the effects of clearance on the bearing damping.

Figure 1. Schematic of a hydrodynamic bearing and the fluid velocity distribution.

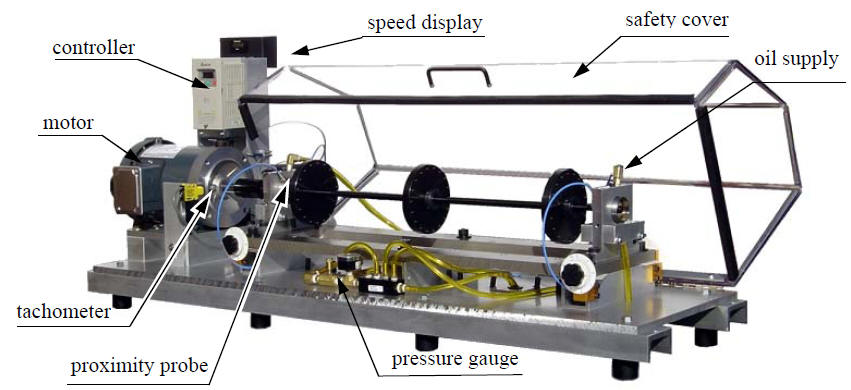

Figure 2. Rotor Dynamics Simulator