Diagnostics of Induction Motor with Broken Bars Using Motor Current Signature Analysis (MCSA)

Lin Liu & Suri GaneriwalaSpectraQuest Inc., 8227 Hermitage Road, Richmond, VA 23228

Published: January, 01 2006

Abstract

Using a Machinery Fault SimulatorTM (MFS) machine, we studied the diagnostics of the common types of fault in induction motors by motor current signature analysis (MCSA) as well as vibration analysis. The faults studied include both electrical and mechanical defects. Specifically, they are broken rotor bar, shorted stator wiring, and motor bearing defect. This is the first of a series of our tech notes on the topic of motor diagnostics.

Introduction

The test is performed on a Machinery Fault SimulatorTM (MFS) made by SpectraQuest.

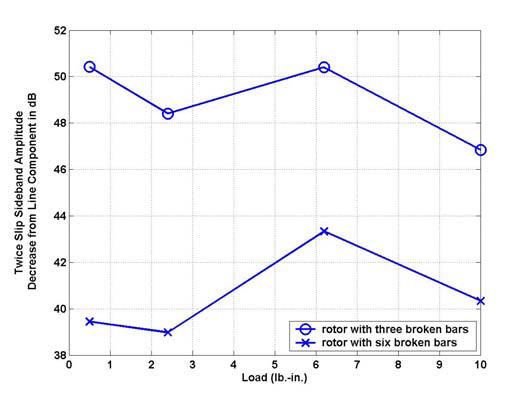

In this study, we have two rotors with different numbers of broken bars. One rotor has three bars broke, and the other one has six bars broke.

Three motors are tested and they are: a good motor, the motor with three broken bars, and the motor with six broken bars. During the test, the power supply line frequency is fixed at 35 Hz by the motor controller. A tachometer detects the rotor speed and the speed is recorded for each test. From the line frequency and the rotor speed data, the per unit slip data can be obtained.

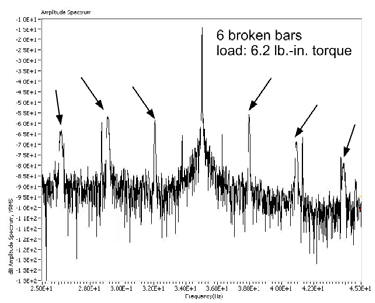

Fig 1: Current Spectrum for Rotor with Three Rotor Bars Broken

Fig 2: Effect of Load on Amplitude Decrease between Twice Slip Sideband and Line Component