The WTDS provides a basic setup for performing drivetrain experiments and for learning vibration signatures of gearbox and bearing malfunctions. However, a detailed investigation of particular and more advance vibration phenomena will require additional attachments and fixtures which are available through optional kits.

|

Bearing Fault Kit (G-BFK-1) |

- Learn waveform and spectra of classic bearing defects.

- Learn about signal processing issues such as averaging techniques, leakage, and spectral resolution on determining bearing faults.

- Perform experiments with increasing severity of defects.

- Determine why an ultra-high resolution spectrum is needed to diagnose a bearing fault when fault frequencies are located close to multiples rotational speed.

- Learn how a large signal can mask adjoining low amplitude signal due to spectra leakage.

- The kit consists of one inner race defect, one outer race defect, one with ball defect, and one combination of defects.

|  |

Planetary Gearbox Bearing Fault Kit (G-BFK-P) |

- Study bearing faults in planetary gearbox

- The kit consists of two different levels of inner race fault and two different levels of needle fault

- Perform experiments with increasing severity of defects.

- Determine why an ultra-high resolution spectrum is needed to diagnose a bearing fault when fault frequencies are located close to multiples rotational speed.

- Learn how a large signal can mask adjoining low amplitude signal due to spectra leakage.

- The kit consists of one inner race defect, one outer race defect, one with ball defect, and one combination of defects.

| |

Radial Bearing Loader (G-RBL) |

- Investigate bearing radial loading effects.

- Understand bearing failure signature as a function of load and rotational speed.

- Compare vibration signature between loaded and unloaded bearings.

- Study outer race bearing fault signature as a function of load location.

- The kit consists of one mechanical bearing loader

- The kit consists of one inner race defect, one outer race defect, one with ball defect, and one combination of defects.

| |

Defective spur gears (G-SDG) |

- Study the effect of damaged tooth in gearboxes.

- Apply phase demodulation signal analysis to detect gear damage.

- Investigate backlash between mating gears.

- The kit consists of one missing tooth gear, one chipped tooth gear, one root crack gear, and one surface wear gear

- The kit consists of one mechanical bearing loader

- The kit consists of one inner race defect, one outer race defect, one with ball defect, and one combination of defects.

|  |

Defective planetary gears (G-PDG) |

- Study the effect of damaged planetary gears.

- Apply phase demodulation signal analysis to detect gear damage.

- The kit consists of one missing tooth gear, one chipped tooth gear, one root crack gear, and one surface wear gear

- The kit consists of one missing tooth gear, one chipped tooth gear, one root crack gear, and one surface wear gear

- The kit consists of one mechanical bearing loader

- The kit consists of one inner race defect, one outer race defect, one with ball defect, and one combination of defects.

| |

Eccentric Spur Gear (G-ESG) |

- Study the effects of eccentric spur gear.

- Measure the vibration signature of eccentric gears.

- The kit consists of one eccentric spur gear.

- The kit consists of one missing tooth gear, one chipped tooth gear, one root crack gear, and one surface wear gear

- The kit consists of one mechanical bearing loader

- The kit consists of one inner race defect, one outer race defect, one with ball defect, and one combination of defects.

|  |

Helical gears set (G-HG) |

- Study the helical gears parallel shaft gearbox.

- Compare vibration signature between spur and helical gears.

- The kit consists of four helical gears to replace standard spur gears in gearbox

- The kit consists of one missing tooth gear, one chipped tooth gear, one root crack gear, and one surface wear gear

- The kit consists of one mechanical bearing loader

- The kit consists of one inner race defect, one outer race defect, one with ball defect, and one combination of defects.

|  |

Defective helical gears (G-HDG) |

- Study the effect of damaged helical gears.

- Apply phase demodulation signal analysis to detect gear damage.

- The kit consists of one gear with chipped tooth and one gear with missing tooth,and one gear with surface defect

- Requires G-HG

- The kit consists of one mechanical bearing loader

- The kit consists of one inner race defect, one outer race defect, one with ball defect, and one combination of defects.

|  |

Torque transducer with built encoder on input shaft (G-TOR) |

- Measure the torque on the input shaft.

- Study torque variation through full rotation cycle.

- Track shaft position in signal analysis.

- The kit consists of one 20 N.m torque meter with built-in 360 pulse encoder

- The kit consists of one mechanical bearing loader

- The kit consists of one inner race defect, one outer race defect, one with ball defect, and one combination of defects.

|  |

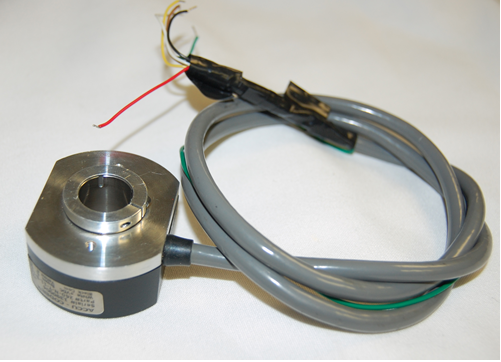

Shaft encoder (G-ENC) |

- Measure transmission error in the gearbox by comparing input and output rotation.

- The kit consists of one 360 pulse per revolution encoder and once per revolution index

- Track shaft position in signal analysis.

- The kit consists of one 20 N.m torque meter with built-in 360 pulse encoder

- The kit consists of one mechanical bearing loader

- The kit consists of one inner race defect, one outer race defect, one with ball defect, and one combination of defects.

|  |

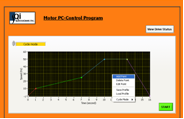

PC Motor Control Kit (G-PCK) |

- Operate DDS from remote location.

- Pre-program speed acceleration, deceleration, and length of run to meet exact requirements.

- The kit consists of PC software, one interface module to motor drive and cables.

- The kit consists of one 20 N.m torque meter with built-in 360 pulse encoder

- The kit consists of one mechanical bearing loader

- The kit consists of one inner race defect, one outer race defect, one with ball defect, and one combination of defects.

|  |

PC Load Control Kit (G-PCLK) |

- Operate magnetic brake from remote location.

- Pre-program load profiles of run to meet exact requirements.

- The kit consists of PC software, one interface module to magnetic brake and cables.

- The kit consists of one 20 N.m torque meter with built-in 360 pulse encoder

- The kit consists of one mechanical bearing loader

- The kit consists of one inner race defect, one outer race defect, one with ball defect, and one combination of defects.

| |

Radial Bearing Loader Force Transducer (G-RBFT) |

- Measure the radial load applied by the mechanically operated bearing loader.

- The kit consists of one transducer measuring radial force and one matching signal conditioner.

- The kit consists of PC software, one interface module to magnetic brake and cables.

- The kit consists of one 20 N.m torque meter with built-in 360 pulse encoder

- The kit consists of one mechanical bearing loader

- The kit consists of one inner race defect, one outer race defect, one with ball defect, and one combination of defects.

| |