An Ideal Tool for Optimizing Your Vibration Class Curriculum

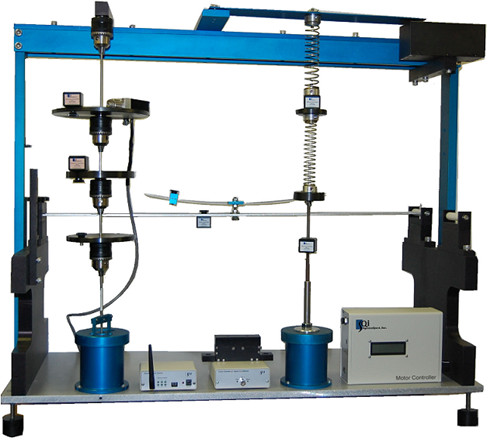

The Vibration Fundamentals Training System (alias VFT) is a turn-key integrated educational package for teaching/learning the fundamental principles of mechanical vibration as well as engineering mechanics. It provides both a comprehensive hands-on experimental device and an instrumentation package including wireless sensors for performing laboratory exercises to enhance student understanding of vibration theory.

The VFT clearly brings classical theory to life by providing a convenient mean to validate predictions and to demonstrate the influence of parameter changes on system response visually. Students can perform virtual experiments using the vibration simulation software and then verify the results with actual experiments thereby reinforcing the learning of difficult principles. The VFT provides an ideal tool for damping free vibration experiments using the wireless sensors without affected by the damping associated with the sensor cables. It is a perfect tool for teaching mechanical vibration courses both at under graduate and graduate levels.

With an increase in high speed manufacturing and automation, it has become more important to use the theory of vibration for design and maintenance of machinery. This vibration theory is even more important in the monitoring and diagnosis of machinery malfunctions. Considering the importance and complexity of vibration principles, a course curriculum should include laboratory demonstration and hands-on experiments to help students understand the somewhat abstract concepts of vibration. To this date, most academic institutions include only theoretical lectures without laboratory exercises due a lack of an apparatus combined with an instrumentation setup. With SpectraQuest’s VFT, this deficiency has been resolved making hands-on vibration teaching now possible.

Controlled Experiments Expedite the Learning

SpectraQuest’s Vibration Fundamentals Training System (VFT) is an innovative tool you can use for teaching the fundamental principles of mechanical vibration. The VFT is well researched and designed for immediate implementation for vibration laboratory development. It is can be easily integrated with a typical vibration course taught at most institutions. The VFT provides a comprehensive hands-on experimental device, an instrumentation package, and experimental program with course curriculum for performing laboratory exercises to enhance student understanding of vibration theory. The bench-top apparatus has a spacious modular design featuring versatility, operational simplicity, and robustness. Each component is machined to high tolerances so it can be operated without conflicting vibration in a totally controlled environment. The instrumentation package includes wireless less accelerometers and transducers, precision servomotor for excitation, tachometer, and four channels simultaneously sampled data acquisition hardware, signal conditioners, and time and frequency domain analysis software. Also included are a software simulation of theory and a well-defined experimental program for free and forced vibration experiments ranging from single degree of freedom spring mass to continuous beam with different boundary conditions.

Students can perform both hands-on and virtual experiments to optimize the learning. The VFT is designed to perform both free and forced vibration experiments with and without damping. The basic VFT frame consists of two identical test stations mounted on a portable structure. It features into changeable restraint fixtures, optional force transducers to measure the support reactions, sensors to measure deflection and acceleration, and a variable frequency rotary shaker for forced excitation. It allows for the first time to perform almost damping free vibration experiments tp verify the theory using SpectraQuest in-house developed wireless sensor technology.

Benefits

Clarify difficult concepts of vibration theory by performing hands-on controlled experiments

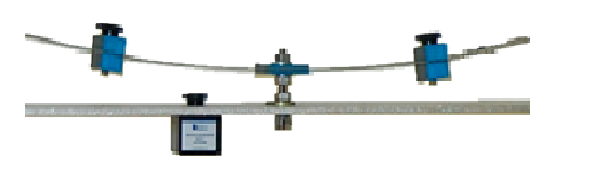

Perform both free and forced natural vibration experiments without damping for the first time using SpectraQuest developed wireless sensors.

Validate theoretical predictions of natural frequencies, mode shapes, and frequency response as a function of frequency, boundary conditions, geometry, and materials

Validate theoretical concepts by comparing experimental results with the computer simulation of the vibration theory

Determine the detrimental effects of vibration load transmission to the support structure and component fatigue life

Learn to control vibration amplitude using tuned mass dampers and damping treatments

Learn vibration measurement transducers, signal processing, data acquisition and data analysis

Features

- Fully integrated turn-key package consisting of comprehensive experimental device, wireless sensors, data acquisition instrumentation, analysis software, course curriculum, exercise book, and simulation software for virtual experimentation

- Robust, user friendly, modular, and compact bench-top device for performing controlled experiments

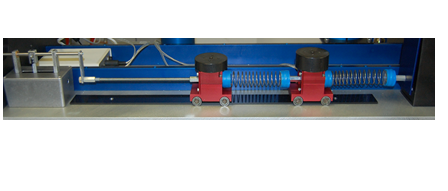

- Experimental setup for single and two-degrees of freedom spring-mass system (with and without damping)

- One and two-degrees of freedom torsional vibration (with and without damping)

- Vibration control experiments with viscoelastic damping and tuned-mass-damper

- Full experimental setup for beams with different boundary conditions, material, geometry, and length to understand effects on natural frequency and mode shapes

- User friendly software with pre-defined experiments integrated with data acquisition and data analysis

- Virtual experiment capabilities to learn the effects of parameters for each type of test configuration

Wireless Sensors Simply Experimentation and Enhance Learning Experience

Cables are often a source of problem due to entanglement and damping associated with them. Cables require special handling during any experimental procedure. They also created hard to characterize unwanted damping. Both of these issues have been solved by SpectraQuest VFT system. We have developed wireless sensors that eliminated both of these problems. Our proprietary algorithm enables simultaneous acquisition of data from all sensors, thus making it possible to obtain accurate phase information and the mode shapes.

Data Acquisition and Analysis Instrumentation

The VFT is equipped with wireless transducers, SpectraQuest’s proprietary 4 channel simultaneously sampled data acquisition (DAQ) system; data analysis software with automated setup for performing each experiment, simulation software, motor control module, multi-featured display, and mounting hardware/tooling. Transducers are provided for the measurement of acceleration, force, and rotational speed. The DAQ system samples all channel simultaneously enabling accurate calculation of mode shapes. Easy to use software automates steps to conduct each experiment and display the results. Students can perform time and frequency domain analysis, read data to do calculations and compare them with theoretical predictions.

The DAQ hardware/software is fully integrated with the excitation motor operation and control. The user can send speed command to control the excitation frequency or a sine sweep can be applied to obtain the full frequency response information over the frequency range of interest. All experimental and data collection setups are pre-defined so that students can focus on the results. The user friendly software is a powerful tool for basic signal processing. Simple and intuitive interface allows fast and easy operation. The signal analysis modules include data presentations of time waveform, FFT spectrum, and frequency response function (FRF). Superimposed data comparison of two data sets is also possible.

Vibration Simulation/Animation

| Vibration fundamentals simulation software is designed to teach basic concepts using a new interactive and visual simulation technique. The student can perform virtual experiments on various topics by changing the parameters of a vibratory system and see how the system behavior is affected. The effect is displayed dynamically. The vivid visualization enhances the learning and clarification. A spring-mass-damper system is used to animate the vibration response. A multi-plot option can be used to compare their effects on vibration response. Therefore, instead of deriving the equations, the user can go one step further, “play and see” the vibration behavior. The software includes the most common topics of a typical vibration course. |  |

High Value Combination Packages

The VFT is available in various packages providing you with all of the components necessary for a turnkey training system:

| Package # 1 : | Basic Vibration Fundamentals Trainer plus kits for Spring mass, beam and torsion studies along with wireless sensors |

| Package # 2 : | Basic Vibration Fundamentals Trainer plus kits for Spring mass, beam, torsion, pendulum and vibration control studies along with wireless sensors |

| Package # 3 : | Basic Vibration Fundamentals Trainer plus kits for Spring mass, beam, torsion, pendulum and vibration control studies along with wireless sensors and force transducers |

| Option kit | | PKG 1 | PKG 2 | PKG 3 |

|---|

| Spring Mass Module (vertical arrangement) | VFT – SMK | x | x | x |

| Beam Vibration Module | VFT-BK | x | x | x |

| Torsional Vibration Module (vertical arrangement) | VFT-TK | x | x | x |

| Sensor Kit | VFT-SK | x | x | x |

| Pendulum Vibration Module | VFT-PK | | x | x |

| Vibration Control Study Module | VFT-VCK | | x | x |

| Vibration Transmissibility Module | VFT-FT | | | x |