Innovative Platform for Bearing Prognostic Research

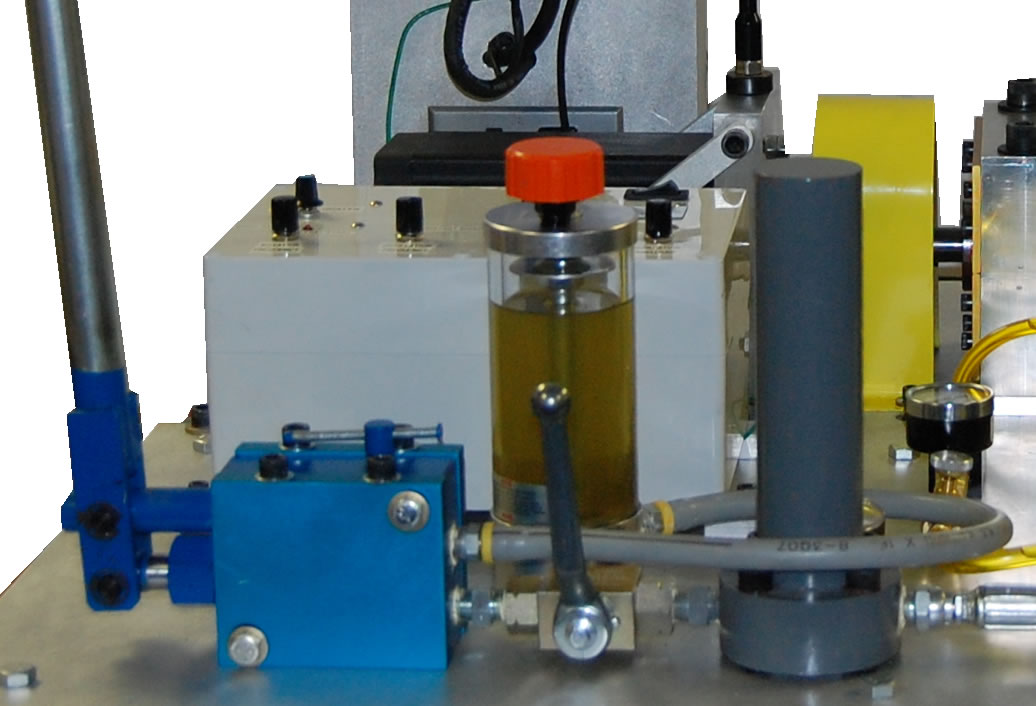

SpectraQuest introduces an innovative Bearing Prognostics Simulator (BPS) for conducting a fundamental research in bearing wear and in modeling bearing damage evolution process. An outstanding feature of the BPS is the inclusion of SpectraQuest’s proprietary transducers for measuring bearing friction torque and transverse and axial loads applied to the bearing. The BPS can be driven in three software selectable modes

- a constant rotational speed

- purely oscillatory motion, and

- oscillatory excitation superimposed on rotation

Experiments can be performed on rolling element bearing, pressurized fluid lubricated bearings, and the grease lubricated bearings. The friction torque and the load transducers provide unique data, previously not available, for understanding bearing prognostics signature and modeling bearing failure mechanisms. The BPS provides an opportunity to develop a predictive model of bearing remaining life based on routine condition monitoring measurement. The torque transducer is sensitive enough to measure the small frictional torque bearing resistance under several thousand pounds of transverse/axial load. The BPS can also be obtained with fluid film lubricated support bearings for minimizing extraneous noise. A higher rotational speed and loading versions are also available.

A Smart Design for Performing Accelerated Run-to-Failure Tests

Bearings are critical for operation of rotating machinery. Unexpected bearing failures are costly; resulting in downtime, production loss, and irreversible damage to the machinery. Most condition monitoring programs routinely measure bearing vibration and perform signature analysis to assess its health, which are trended to assess severity of the damage. This assessment is strictly based on historical data and/or statistical analysis resulting in miscalls and/or premature replacement of a good bearing and loss of production. To date a prognostics model of bearing health has been elusive, probably due a lack of accelerated run-to-failure test-rig and transducers for measurement of key parameters. SpectraQuest’s BPS addresses both of these deficiencies.

Benefits

Conduct fundamental research in bearing wear evolution

Develop model for damage propagation mechanisms of rolling element bearings, pressurized fluid film bearings, and the grease lubricated bearings

Understand bearing failure mechanisms as a function of load, rotational speed, and the oscillatory motion of the bearing

Develop predictive models of the bearing remaining life based on damage evolution, operating speed, amplitude and type of the loading

Research signal processing techniques and sensor types for condition monitoring of bearings for prognostics

Study correlation among vibration, motor current, load, friction and noise spectra

Verify model-based diagnostics/prognostics algorithms

Features

- Modular, robust and versatile bench top device for conducting bearing prognostics research

- Simultaneous measurement of radial or axial bearing load and friction torque

- Smart friction torque transducer designed for measuring small friction load in presence of heavy applied force

- Fully programmable motor input parameters for constant speed and for oscillatory motion with and without rotational speed

- Configurable to test rolling element bearing, grease lubricated bearing, and fluid film bearing in one unit

- Instrumented easy to operate hydraulic bearing loading system

- Easy installation and removal of test bearing

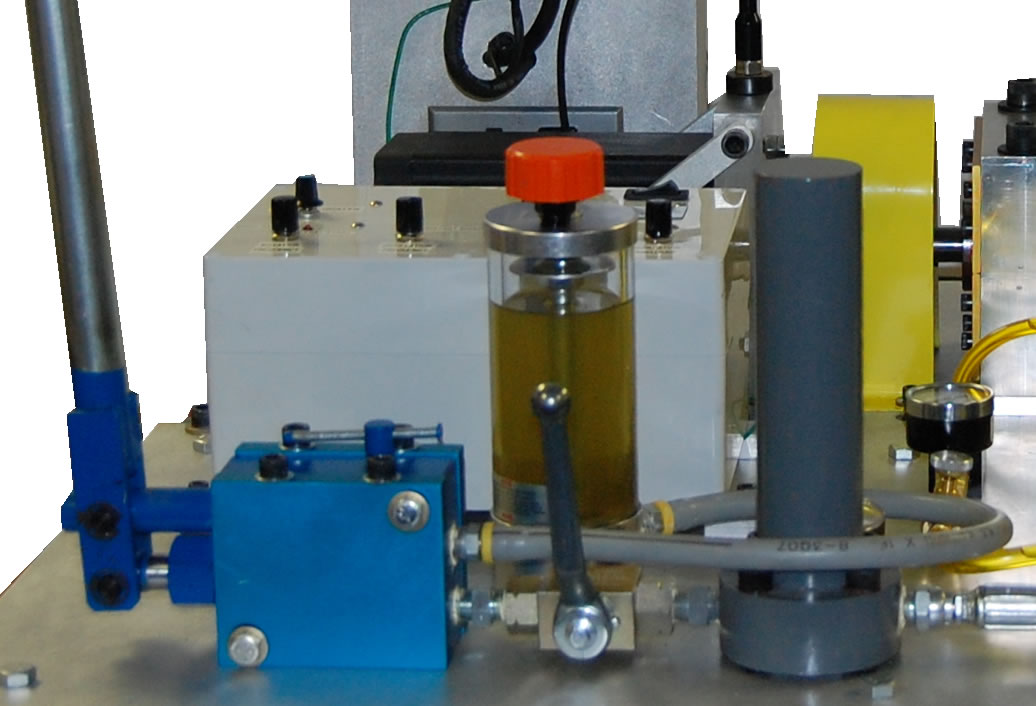

An Instrumented Loading System for Measuring Applied Force

SpectraQuest’s Bearing Prognostics Simulator (BPS) is designed to hydraulically overload bearings both transversely and axially. Tests are then performed to observe damage initiation to propagation on different types of bearings. The rig can be operated under three different modes

- constant rotational speed

- oscillatory motion, and

- oscillatory excitation superimposed on rotation

A PC programmable variable frequency AC induction motor is used to provide a pure rotary motion up to 6,000 revolutions per minute (a higher speed version is available upon request), while a software configurable stepper motor is used for oscillatory motion or low rotary speed (10-180rpm). Both types of motors can be easily and interchangeably mounted on the BPS platform. |  |

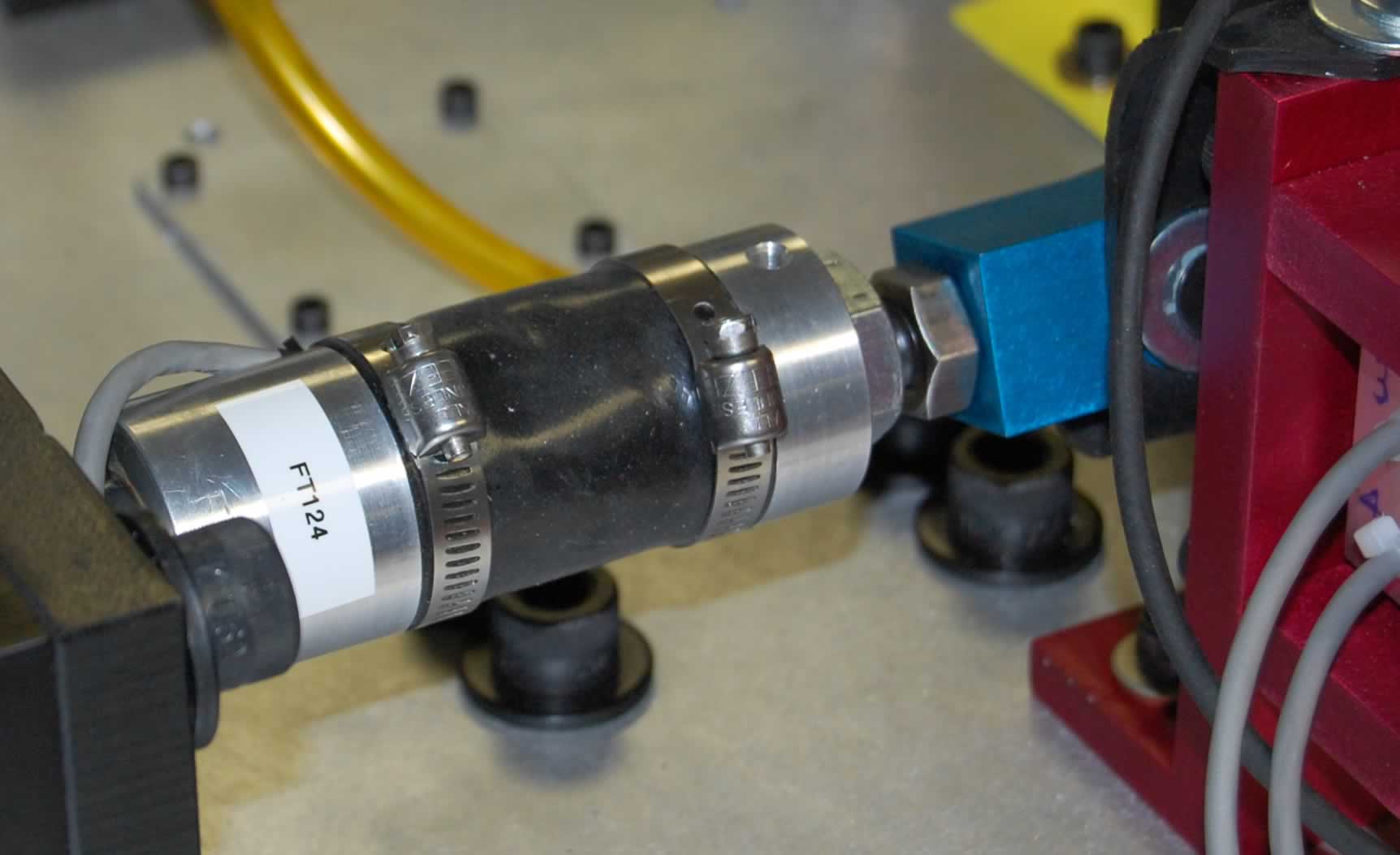

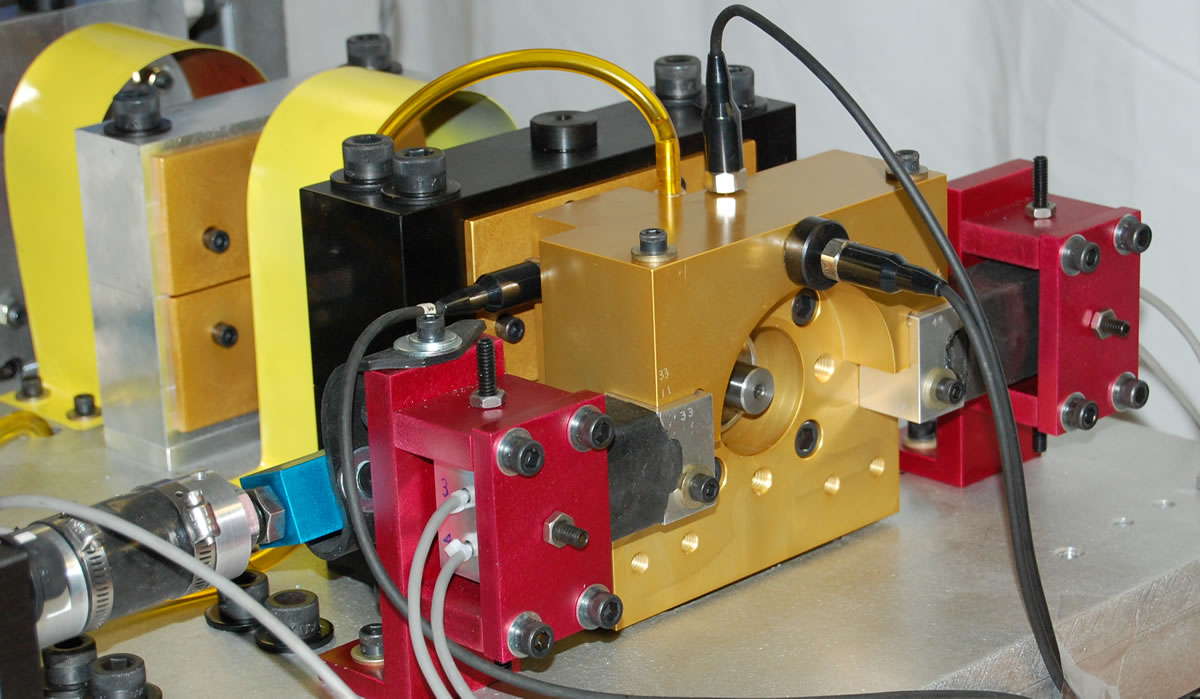

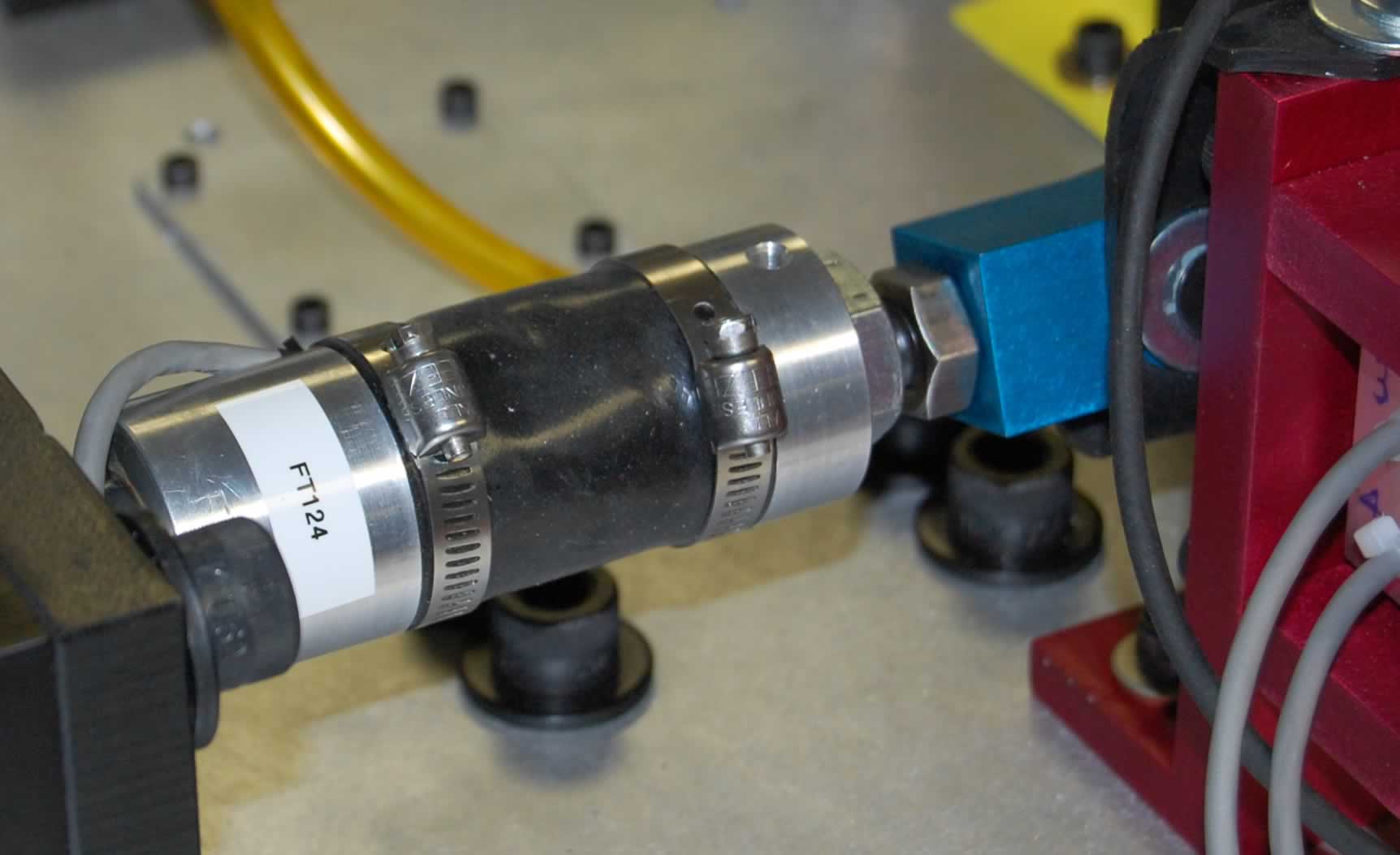

| The test bearings are configured overhung and are supported on two rows of heavy duty rlling element bearings. A fluid film support bearing system can be provided upon customer request. The overhung configuration is selected for ease of loading the bearings and the measurement of the frictional torque generated during the test. An instrumented hydraulic system is used for axial and transverse loading. The hydraulic system consists of an oil reservoir, oil valve, hand pump, pressure gauge, load transducer and loading cylinder. Radial loads up to 6,000 pounds (~ 27 KN) can be added to the bearing housing. A force transducer is placed between the loading cylinder and the test bearing housing to measure the applied force. |  |

| This strain gage based custom force transducer was developed in-house for measuring the applied force and performing signature analysis as a function of wear damage growth. The transducer design ensures that the orientation and the point of application can be adjusted such that the load is applied along the center line of the bearing, which is particularly important with increasing loads. |  |

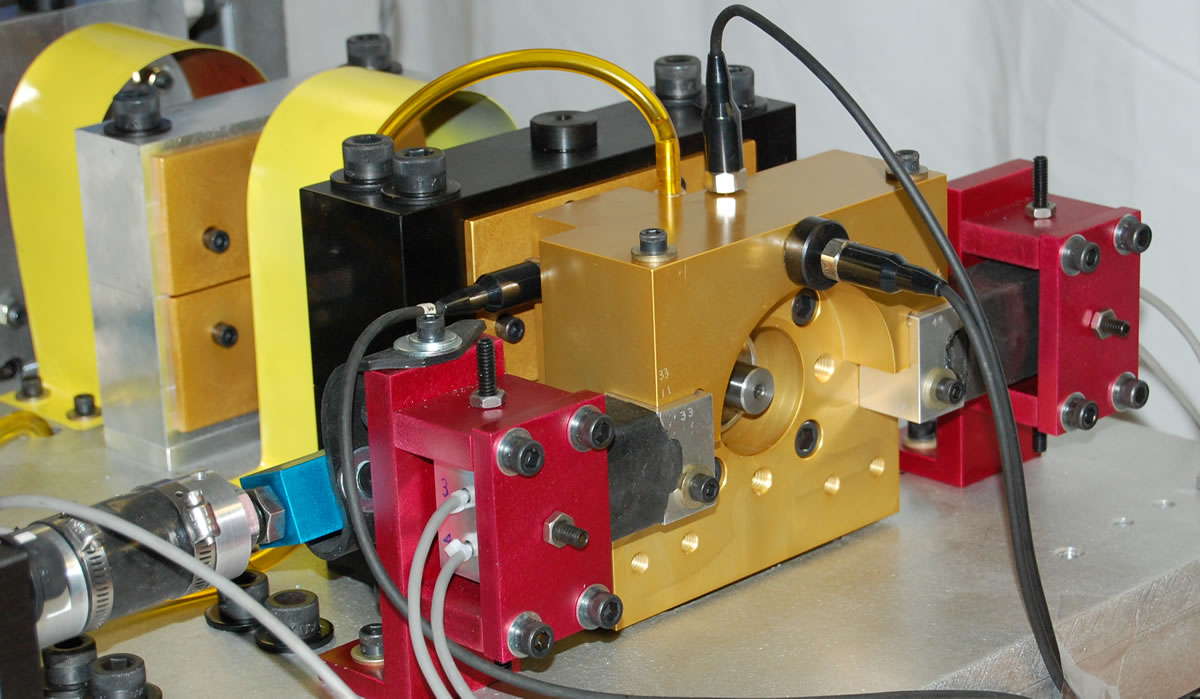

Ideal Tool for Characterizing Bearing Friction Torque

| As bearing damage progresses, the characteristics of the frictional force between rotating and the stationary components of the bearing are expected to evolve. A bearing friction torque transducer system was designed to accomplish this task. This transducer design featured innovative ideas to cancel the torque associated with the bending forces and minimize the effects of supporting structure. It is also possible to make field adjustments to eliminate the effects of increased lateral loading on the support deformation. This smart design makes it possible to obtain bearing frictional torque information as a function of damage growth.The results can be used to characterize bearing failure mechanisms for developing a prognostics model. |  |

The BPS is Heavy-Duty and Easily Configurable

The BPS is designed to remove and install test bearings easily. The unit is adaptable to install different type of rolling element bearings, fluid film bearings, and grease lubricated bearings. A complete oil circulation system including a pump is provided for running with fluid film test bearings. The BPS is built robust and provides substantial lateral stiffness such that the support deformation is not objectionable when several thousands of pound force is applied to the bearing under test. The test bearing housing is designed to accommodate the placement and removal of bearings easily. Mountings are provided for installation of transducers. The BPS frame is mounted on vibration isolators to minimize the transmission of the environmental vibration.

Transducers and DAQ

Accelerometers can be installed on the bearing housing to measure the vibrations in all three directions. Thermocouples can also be attached to the outer race of the bearing for temperature monitoring and analysis and oil debris can be collected for lubrication and bearings condition analysis. Other transducers can also be installed per customers’ request. Data acquisition hardware and software are also available from Spectra Quest and ready to do time domain and frequency domain signal analysis.

High Value Combination Packages

The BPS is available in various high value combination packages. From basic to comprehensive, each package is designed to provide you with all the tools needed to study and model bearing faults.

| Package # 1 : | Basic Rolling Bearing Prognostic Simulator plus kits for applied force and friction torque measurements |

| Package # 2 : | Basic Rolling Bearing Prognostic Simulator plus kits for applied force and friction torque measurements, stepper motor and grease bearings |

| Package # 3 : | Basic Fluid Bearing Prognostic Simulator plus kits for applied force and friction torque measurements |

| Package # 4 : | Basic Fluid Bearing Prognostic Simulator plus kits for applied force and friction torque measurements, stepper motor and grease bearings |

| Package # 5 : | Basic Rolling and Fluid Bearing Prognostic Simulator plus kits for applied force and friction torque measurements |

| Package # 6 : | Basic Rolling and Fluid Bearing Prognostic Simulator plus kits for applied force and friction torque measurements, stepper motor and grease bearings |

| Option kit | | PKG 1 | PKG 2 | PKG 3 | PKG 4 | PKG 5 | PKG 6 |

|---|

| Basic Rolling Bearing Prognostic Simulator | BPSR2010 | x | x | | | | |

| Basic Rolling and Fluid Bearing Prognostic Simulator | BPSC2010 | | | | | x | x |

| Basic Fluid Bearing Prognostic Simulator | BPSF2010 | | | x | x | | |

| Transverse Force Transducer | BP-TFT | x | x | x | x | x | x |

| Friction Torque Transducer | BP-FTT | x | x | x | x | x | x |

| Stepper Motor | BP-STEP | | x | | x | | x |

| Grease Lubricated Bearing | BP-GR | | x | | x | | x |