Observations of Dynamic Responses of Misalignments

Mohsen Nakhaeinejad & Suri GaneriwalaSpectraQuest Inc., 8227 Hermitage Road, Richmond, VA 23228

Tel: (804)261-3300 www.spectraquest.com

Published: September, 01 2009

Abstract

Experiments investigated dynamic effects of angular and parallel misalignments in rotating machinery on machine behavior. Different levels of angular and parallel misalignments were applied to the SpectraQuest Machinery Fault SimulatorTM (MFS) rigid, rubber and helical beam couplings. For each case, shaft speed, motor and bearings vibrations, and bearing forces were measured. Forces and vibration signals were studied in time and frequency domain. Results indicate strong effect of coupling stiffness on vibrations and forces. Severe parallel and angular misalignments can generate low frequency modulations in vibration signals. Also, axial forces due to misalignment were observed in angular and parallel misalignments

Keywords: Misalignment, Rotating Machinery, Fault Diagnostics, Vibrations

Introduction

Misalignment in rotating machinery is one of the most common faults causing other faults and machine failure. It causes over 70% of rotating machinery vibration problems [1]. A misaligned rotor generates bearing forces and excessive vibrations making diagnostic process more difficult. A perfect alignment can never be achieved practically and misalignment is always present. Also, many factors such as thermal growth, uneven applied loads, inappropriate foundations, etc., can disturb the alignment. Vibration spectrum analysis has been a common tool for misalignment detections for a while. In-depth study of dynamic forces and vibrations is helpful for understanding and diagnosing of misalignments. There have been many research on analytical study of misalignments considering vibration and dynamic forces [2-5]. However, there have been relatively limited experimental studies [6-8] in full-monitoring of misaligned rotors. This study was aimed to investigate experimentally effects of misalignment type and levels, and coupling materials on machine response.

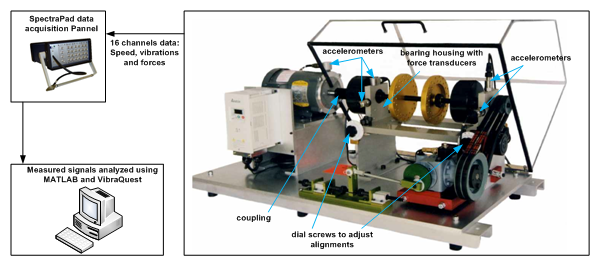

The SpectraQuest's Machinery Fault SimulatorTM (MFS) (Fig. 1), a comprehensive test-bed for in-depth studies of the most common machinery faults, was used for experiments. Three different couplings were used, angular and parallel misalignments in different levels were introduced, the machine was fully monitored through sixteen channels of speed, vibrations and forces during each experiment, and collected data were analyzed in time- and frequency domains.

Experiments

The SpectraQuest's Machinery Fault SimulatorTM (MFS) was used for misalignment experiments. MFS is a comprehensive test-bed for rotating machinery experiments and for in-depth studies of the most common machinery faults including misalignments. MFS consists of an induction motor coupled to the main shaft supported by two rolling element bearings.

Fig 1: SpectraQuest's Machinery Fault Simulator (MFS) and SpectraPad data acquisition board were used for misalignment experiments

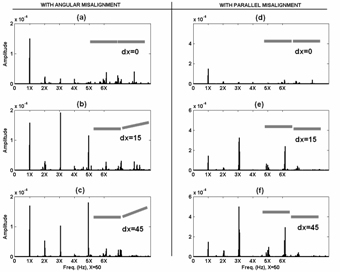

Fig 5: Power spectrum of outboard bearing horizontal vibrations for angular (left) and parallel (right) misalignments. a,d: aligned; b,e: low misalignment; c,f: severe misalignment (f=50Hz, helical beam coupling)