Research

SpectraQuest products provide test platforms for research in rotor dynamics, gearboxes, drivetrains, machinery fault diagnostics, machinery fault prognostics, condition monitoring, and preventive maintenance. Robust, modular design allows the researcher to easily introduce controlled and calibrated faults and to reconfigure the simulator for different studies.

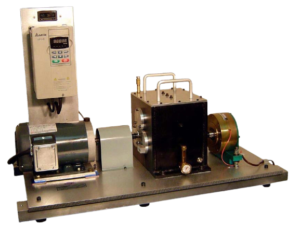

Machinery Fault Simulator (MFS) |

|

The Machinery Fault Simulator (MFS) family is designed to study the signature of common machinery faults, such as unbalance, alignment, resonance, bearing, rotor dynamics, crack shaft, gearbox, belt drive, reciprocating mechanism, mechanical rub, induction motor, pump, compressor, and fan.

|

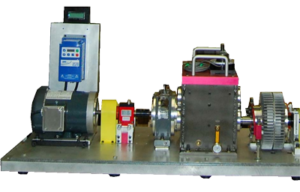

Gearbox Dynamics Simulator (GDS) |

|

The Gearbox Dynamics Simulator (GDS) consists of a two-stage parallel shaft gearbox with rolling bearings and a magnetic brake.

|

Drivetrain Diagnostics Simulator (DDS) |

|

The Drivetrain Diagnostics Simulator (DDS) goes further to research a complete drivetrain, adding a planetary gearbox and heavy loading.

|

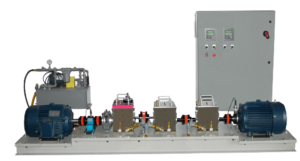

Drivetrain Prognostics Simulator (DPS) |

|

The Drivetrain Prognostics Simulator (DPS) has been specifically designed to simulate industrial drivetrains for diagnostics and prognostics research.

|

Bearing Prognostics Simulator (BPS) |

|

The Bearing Prognostics Simulator (BPS) is for conducting fundamental research in bearing wear and in modeling bearing damage evolution process.

|

Custom Machinery |

|

SpectraQuest has long had experience in making custom machinery to meet our customer’s exact diagnostics machinery needs.

|