Rotating Machinery Diagnosis using Synchro-Squeezing Transform Base Feature Analysis

Budhaditya Hazra8227 Hermitage Road, Richmond, VA 23228

Published: October, 7 2014

Abstract

In this study, we propose a novel signal processing algorithm for condition assessment of gears and bearings and detect failures. The algorithm utilizes the recently developed concepts of synchro-squeezing transform [11] and integrates it with the traditional condition monitoring indicators [15] to detect gear faults. Synchro-squeezing transform is a signal decomposition tool capable of decomposing a multi-component non-stationary signal into AM-FM components that resemble intrinsic mode functions (IMFs). It is in fact a type of time-frequency reassignment algorithm that works by reallocating the CWT coefficients based on the frequency information, to obtain a sharper representation in the time-frequency plane.

Rotating machinery diagnostics, Synchro-squeezing transform (SST), Condition indicators

Introduction: Faults in gears and bearings can lead to catastrophic failures in critical rotating machinery infrastructure leading to substantial downtime, significant monetary losses and considerable socio-economic impacts. Ensuring their smooth operation requires maintenance, so that any change in the condition such as deterioration or damage can be detected in a timely manner. This can be accomplished through signal processing of gear and bearing vibration signatures. In this study, we propose a novel signal processing algorithm for condition assessment of gears and bearings and detect failures at their incipient stages of development. The algorithm utilizes the recently developed concepts of synchro-squeezing transform [11] and integrates it with the traditional condition monitoring indicators [15] to detect gear faults.

In order to accomplish accurate fault diagnosis, it is important that the acquired rotating machinery vibration signals have good signal to noise ratio and less complexity. The complexity of rotating machinery signals are attributed to individual contributions from different sources like gears, bearings, rotors, and motors etc. to the overall vibration response. The problem is compounded further in presence of noise and transients from faulty machine components. This can be addressed by considering the extraction of meaningful components from the mixed signals. The other alternative is to consider the signals directly as they evolve and avoid decomposing them into different components and instead make use of a spectral techniques [1] to diagnose faults.

In the direct approach, traditional spectral analysis methods like the Fourier transform (FFT), Cepstrum analysis, and Envelope spectrum analysis, etc., have been reported in the rotating machinery fault diagnosis literature [1, 3, 17, 18]. Recent trends in fault diagnosis have witnessed a paradigm shift to time-frequency representation (TFR) methods like short-time Fourier transform [1, 4], continuous wavelet transform (CWT) [1] discrete wavelet transform (DWT) [5], wavelet packet transform [7], Wigner-Ville distribution (WVD) [4, 6] and their enhanced derivatives. This is attributed to the fact that the gear signals are inherently non-stationary and the transients due to the defects can be better captured using the TFR methods. Time series modeling techniques like (AR, MA, ARMA and VARMA etc.) applied using time-invariant coefficients [1, 2]; have provided attractive options in the family of parametric spectral approaches. Since rotating machinerysignals comprise mainly of time-varying frequency components and amplitudes, the use of Kalman filtering based techniques for modeling time varying ARMA models is worth mentioning [2]. But all of the parametric models suffer from the problem of model order selection which is again an encumbering factor as far as dealing with complex and noisy rotating machinery signals is concerned.

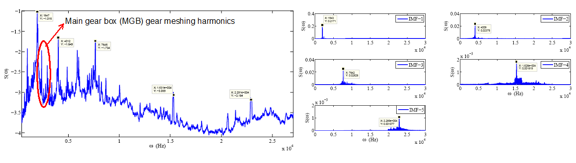

Figure 6: Logarithmic spectra of the bearing data for dataset-1 Figure 7: IMFs from the bearing data (dataset-1)