Cavitation Vibration Signatures of a Centrifugal Pump

Abstract

In this work, a centrifugal pump was tested for its vibration signatures under different operational conditions. Two of the abnormal operating conditions studied are air bubble and cavitation. A transparent plastic cover was used in the experiments to observe the cavitation. It was found that the pump has higher vibration amplitude in the axial direction than in the radial direction. From the experiments, it was also determined that significant amount of air bubbles will increase vibration component associated with impeller vane pass frequency significantly. Cavitation might excite high frequency structural resonance. It might also reduce the impeller vane pass frequency vibration. Although cavitation is less likely to happen on a slow speed pump, it will develop very fast if it happens.

Introduction

A pump is a mechanical device used to move liquids. Mechanical energy is transformed into hydraulic energy at the pump. Pumps can be classified into two categories: displacement pumps and centrifugal pumps. In this work, a centrifugal pump was tested and studied.

The essential elements of a centrifugal pump are:

- the rotating element, consisting of the shaft and the impeller

- the stationary element, consisting of the casing, stuffing boxes, and bearings.

Fig. 1 illustrates the single stage bronze centrifugal pump used in this work. This pump has a single rotating metal impeller. Liquid enters at the center and is thrown outward radially by centrifugal force. The five impeller vanes can be identified in Fig.1 clearly.

Figure 1. Centrifugal Pump

In a centrifugal pump, a rotating element called an impeller is enclosed in a case. The fluid to be pumped enters into the case through the suction piping into the impeller and is forced out the discharge side of the pump by means of centrifugal force pushing the fluid out radially through the impeller. The fluid is discharged at a higher pressure and a higher velocity. The major portion of the velocity energy is then converted into pressure energy by means of a volute or by a set of stationary diffusion vanes surrounding the impeller periphery. In a pump, vibration is caused by the interaction between the moving pump impeller and the stationary parts of the pump such as the volute and the diffuser vanes. Also, vibration is caused by the interaction between the impeller blades and the fluid being pumped.

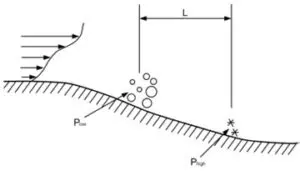

One of the important phenomenon in pump is cavitation. Cavitation occurs when the pressure of the fluid drops below the vapor pressure for the temperature of the fluid. When this pressure drop occurs, whether it is a system pressure drop or a localized pressure drop, voids or cavities (bubbles) will form in the liquid. These bubbles implode or collapse when the fluid moves through impeller to the high pressure side of the pump, causing the impeller to erode. These implosions tear out tiny pieces of the metallic surface near which they implode. This can be very damaging and eventually the impeller will fail. Fig. 2 shows a schematic representation of the cavitation process.

Figure 2. Cavitation

There are three common causes of vapor formation in a liquid:

- Flow separation of a viscous fluid from its guiding surface due to a surface discontinuity.

- The addition of heat to the fluid, raising its vapor pressure (boiling point).

- Reducing the pressure of the fluid to below its vapor pressure.

One important terminology in pump theory is net positive suction head (NPSH). NPSH is a measure of the difference between the total suction head and the fluid vapor pressure. The concept of NPSH is related with cavitation closely. For a specific pump, there are the required NPSH and available NPSH. The required NPSH is the factory suggested value which must be maintained to prevent the happening of cavitation. The available NPSH is the real pressure difference between the suction head and the fluid vapor pressure.

Accessing Full Text

To access the full PDF, please follow these steps. Make sure pop-ups are enabled in your browser.

Steps:

Enable pop-ups if needed

- If the PDF doesn't open in a new tab, pop-ups may be blocked.

- Look for a message near the address bar (top-right corner).

- Click "Allow pop-ups" for this site.

- Refresh the page and try again.